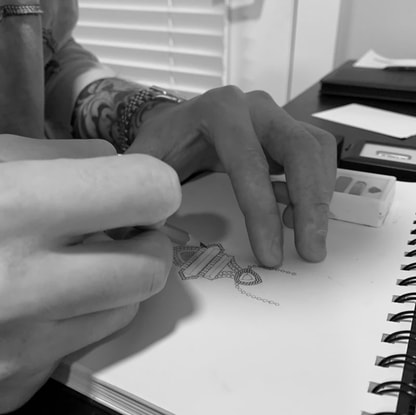

Step 1.

During our initial consultation, we engage in a comprehensive discussion to conceptualize and sketch the ideas that align with the client's vision and preferences. This meticulous process sets the foundation for the creation of a bespoke piece, ensuring that every detail is thoughtfully considered and integrated into the design.

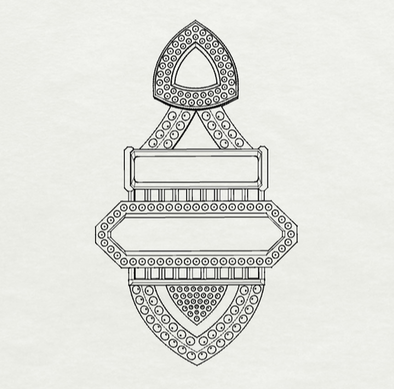

Step 2.

Upon approval of the initial sketch, we transition to using CAD software for precise and detailed design work on the piece. This step ensures accuracy and meticulous craftsmanship in bringing the envisioned creation to fruition.

step 3.

Following the CAD design phase, we furnish a comprehensive 3D render, offering a detailed visual representation of the final piece's appearance. This step ensures clarity and alignment with the client's expectations before moving forward with the crafting process.

step 4.

Upon approval of the 3D model, we proceed to casting it into metal. Our skilled Goldsmith meticulously works the metal, preparing it for stone setting. The final touch involves our master setter personally setting each stone by hand, employing cutting-edge techniques to ensure the utmost precision and deliver exceptional results. This dedication to craftsmanship guarantees that every piece attains the highest standards of quality.

STEP 5.

Following the crafting process, the piece is polished and finished, ensuring a flawless and refined surface. This meticulous attention to detail reflects our commitment to excellence at M.C. Jeweller Originals.